HUIRUI PE pipe for gaseous supply, using imported PE gas-specific mix, is produced by low-temperature and high-speed PE pipe production lines of the world-class pipe equipment manufacturer. The product meets the standards of ISO4437, GB/T 15558.1-2015. Outside diameter: dn20mm~dn630mm. According to customers’ requirements, we can cut and customize the pipe length.

Advantage:

Main application:

HUIRUI PE gas pipe is mainly used to transport natural gas, liquefied petroleum gas (gas state) and artificial coal gas and other types of gas.

Scope of application:

HUIRUI PE gas pipe is prohibited strictly for using as overground indoor pipelines, and can only be used for buried pipelines. It applies to the working temperature at -20 ~ 40℃ , and maximum allowable working pressure is not greater than 1.0Mpa (gauge) of the low pressure gas pipeline.

SDR11 series should be used to transport natural gas, liquefied petroleum gas (gas state) and artificial coal gas; SDR17 series should be used to transport natural gas.

SDR21 Series and SDR26 Series are commonly used for trenchless gas pipeline repair.

Connection method:

HUIRUI PE gas pipe’s connection methods are generally divided into two types - hot melt connection and electrofusion connection. The common principle of PE pipe welding is that polyethylene can generally be melted in the range of 190-240℃ . At this time, if the molten part of pipes is fully contacted and maintains proper pressure (the pressure of electrofusion welding comes from the thermal expansion of polyethylene itself during the welding process), it will can be firmly integrated after cooling. Construction implements CJJ63-2008 “Technical specification for polyethylene (PE) fuel gas pipeline engineering”.

Variety specification:

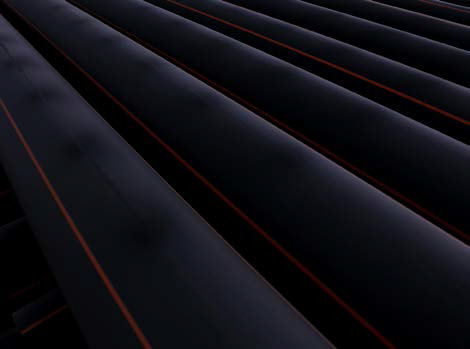

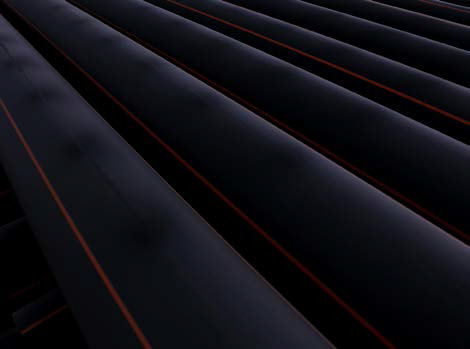

HUIRUI PE gas pipe, according to grades of raw material used, is divided into two grades - PE80 and PE100, and there are four series of size specifications: SDR11, SDR17, SDR21 and SDR26. The color of pipe is black with orange strips. Specifications range is from dn20mm to dn630mm. Length is generally 12 meters each root and small diameter pipe (below dn63mm) can be coil supply.

|